ADVANCED MACHINES

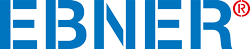

Sendzimir 20 high Mill, advanced cold rolling equipment in the world

- High stiffness and radial rolling force acting on each section of the frame.

- The small diameter of the working roll, the high reduction rate of the pass, up to 60%. Some materials can be rolled into very thin strips without intermediate annealing.

- With axial and radial roll shape adjustment, roll diameter size compensation, rolling line adjustment, and other mechanisms, and the use of hydraulic pressure and hydraulic AGC system, the product has a good shape and high dimensional accuracy.

Precision steel strip with extremely thin thickness, high quality, and high performance that can be rolled

- Thickness Tolerance ≤ ±0.5% t

- Flatness ≤ 0.1um/mm

- Edge camber ≤ 0.5mm/2.5m

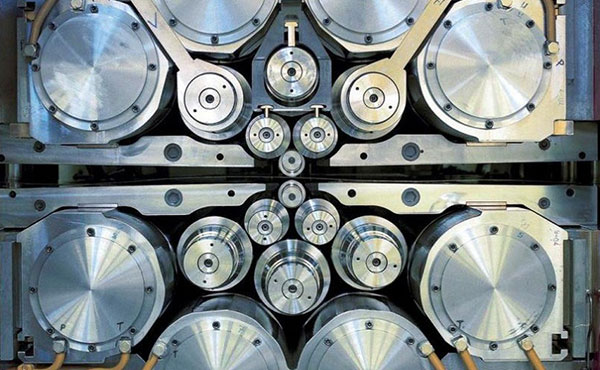

EBNER Bell Annealer

EBNER Bell Annealer

- The technology that revolutionized the heat treatment of steel strip coils.

- Bell annealers achieve shortest possible annealing and cooling times while simultaneously keeping operating costs low.

- The facility can be implemented to comply with the standards required by the automotive industry, in accordance with CQI-9 (AIAG)

Automatic heat treatment production line

- Efficient continuous production, improving production capacity stability

- Precise process control ensures product consistency

- Energy conservation, consumption reduction, and overall cost reduction

- Full process data traceability to enhance quality control capabilities

- High security and human efficiency optimization

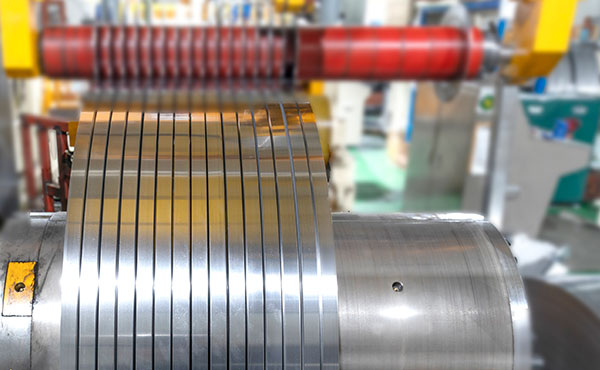

Slitting line

- High precision cutting and tolerance control Adopting a laser positioning+servo tension closed-loop system, equipped with a dynamic correction device, the material utilization rate is significantly improved compared to traditional shearing processes

- Flexible production configuration The modular tool holder design supports quick tool specification switching, and the dual station winding system achieves non-stop winding

- Intelligent Quality Monitoring System

- Energy efficiency optimization and environmental friendliness

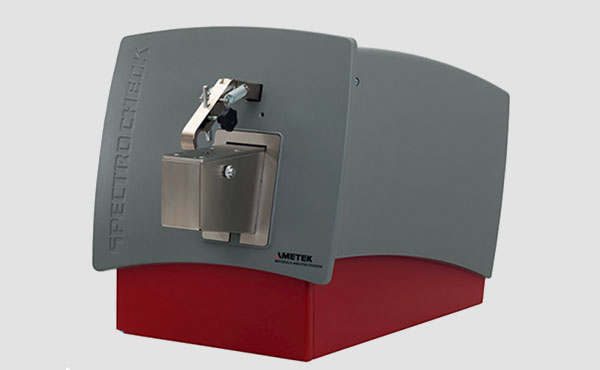

SPECTROCHECK stationary metal analyzer

SPECTROCHECK stationary metal analyzer

- Ideal for metal testing and quality control of iron-, aluminum- and copper-based samples

- Ultra-fast one sample standardization — based on SPECTRO´s Intelligent Calibration Logic (iCAL)

Tension machine

Tension machine

- Test load Fmax = 200KN ; Accuracy = Class 0.5

- The test can be done according to international standards, such as GB, ISO, DIN, ASTM and JIS etc.

EBNER Bell Annealer

EBNER Bell Annealer

SPECTROCHECK stationary metal analyzer

SPECTROCHECK stationary metal analyzer

Tension machine

Tension machine